Real Time Particle Analyzer

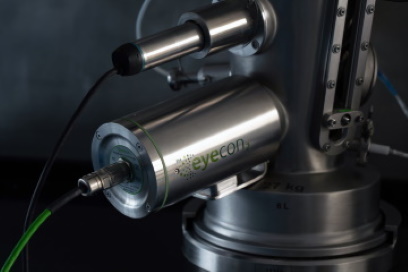

Eyecon2 is a particle sizing and characterizing system which can be used both in-line and at-line for batch production and continuous processes.

Eyecon2 can provide real-time particle size and shape information essential for process understanding and control. Its non-product-contact GMP design makes integration on most processing equipment very simple, commonly using existing viewing ports and therefore requiring no revalidation of the equipment.

Capture the real-time data analysis and profile of your powders and bulk solids with Eyecon2. Troubleshoot and improve end-product goals with particle size and shape data. Adopt automated process control to drive down production cost. Non-product contact measurement minimises risk with hazardous materials. At-line and in-line configurations allow transition from benchtop to in-line integration and evolve with your needs.

Common In-line Applications

- Fluid bed granulation

- Fluid bed coating

- Spheronisation

- Twin screw granulation

- Milling

- Roller compaction

- Extrusion

- Eyecon2 is convertible between in-line and benchtop / at-line configurations.

Benefits

- Non product-contact

- In-line and benchtop

- Real time size & shape data

- Intuitive & user-friendly software

- Particle images

- Highly portable

- GMP compliant

- Industry 4.0 ready

Usage Areas

- Formulation development

- Process investigation

- Quality by Design

- Scale up

- Tech transfer

- Commercial manufacturing

- Continuous Process Verification

- Automated control

EyePASS Particle Analysis Software

Key Features

- Calculation of D-Values (D10, D50, D90, Mean, Median), Particle Size Distribution (PSD), Eccentricity

- Storage of particle image files (JPG)

- Historical data review – view size profiles of previous batches

- User-configurable reports

- Report generation including PDF session report and CSV data file

- Comprehensive user account management including user groups and access privileges

- Alarm settings to notify deviation from ideal process trajectory

Copyright GAMP Services 2024. All Rights Reserved.

Copyright GAMP Services 2024. All Rights Reserved.